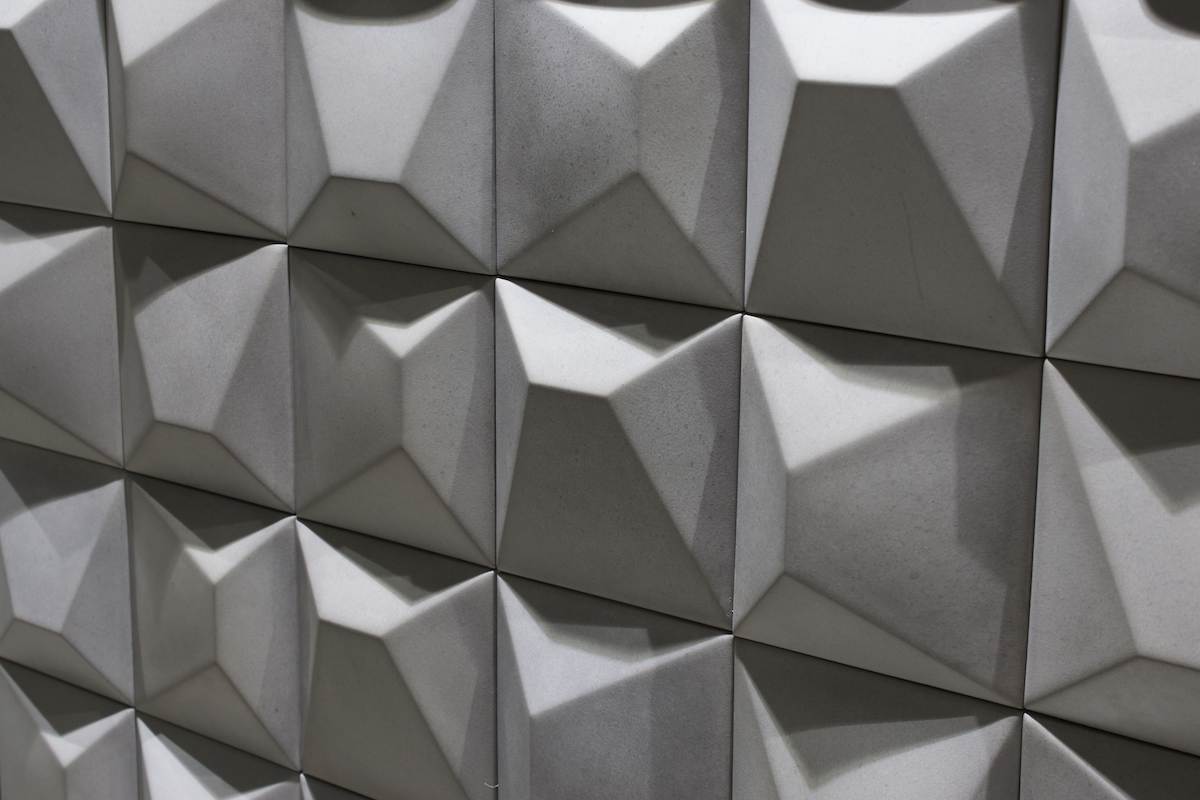

The characteristics and performance of lightweight concrete decorative tiles are dependent on lightweight particles for compressive strength, and according to that, you will get their benefits.

The strength of the aggregates and the strength of the paste made of hardened cement and water are two parameters that affect the strength of lightweight concrete.

The strength and hardness of the various varieties of lightweight aggregate vary greatly, and all but the toughest ones are likely to be weaker than hardened cement-water pastes when used within the typical range of cement concentrations.

The strength of lightweight concrete will typically be lower than that of concrete with regular-weight particles and equal cement content.

Additionally, the strength of the lightweight concrete will be lower with a given cement quantity, the weaker the lightweight aggregates are.

Since the density is low, lightweight aggregate concrete has poor compressive strength. Even the toughest lightweight aggregate concrete is still inferior to cement paste in strength.

The strength of lightweight concrete decreases linearly with the strength of lightweight aggregate. The advantages of lightweight concrete are its lightweight, excellent insulating properties, and fire resistance.

Insulation and Absorption of Sound

Lightweight concrete is ideal for impact and airborne sound absorption, making it a great material for floor screeds and partition walls.

Better sound absorption is provided by airborne or air-contained elements in lightweight concrete. The better the sound insulation, the better the sound absorption. It is appropriate for use on floors and partition walls that require improved sound insulation.

Resistance to Fire

Due to its lower heat conductivity and slower rate of strength loss as temperature rises, lightweight concrete is more fire-resistant than concrete made of ordinary particles.

Due to its decreased heat conductivity, lightweight concrete is more fire-resistant than regular concrete. Since lightweight concrete has a lower density than traditional concrete, it does not expand as quickly when the temperature rises.

As a result, lightweight concrete will experience a decreased rate of strength loss. It stops the fire from spreading quickly and inflicting further harm or loss. The fire victims might not be able to flee if the fire progressed from one room to another. The covering materials ought to be more fire-resistant for this reason.

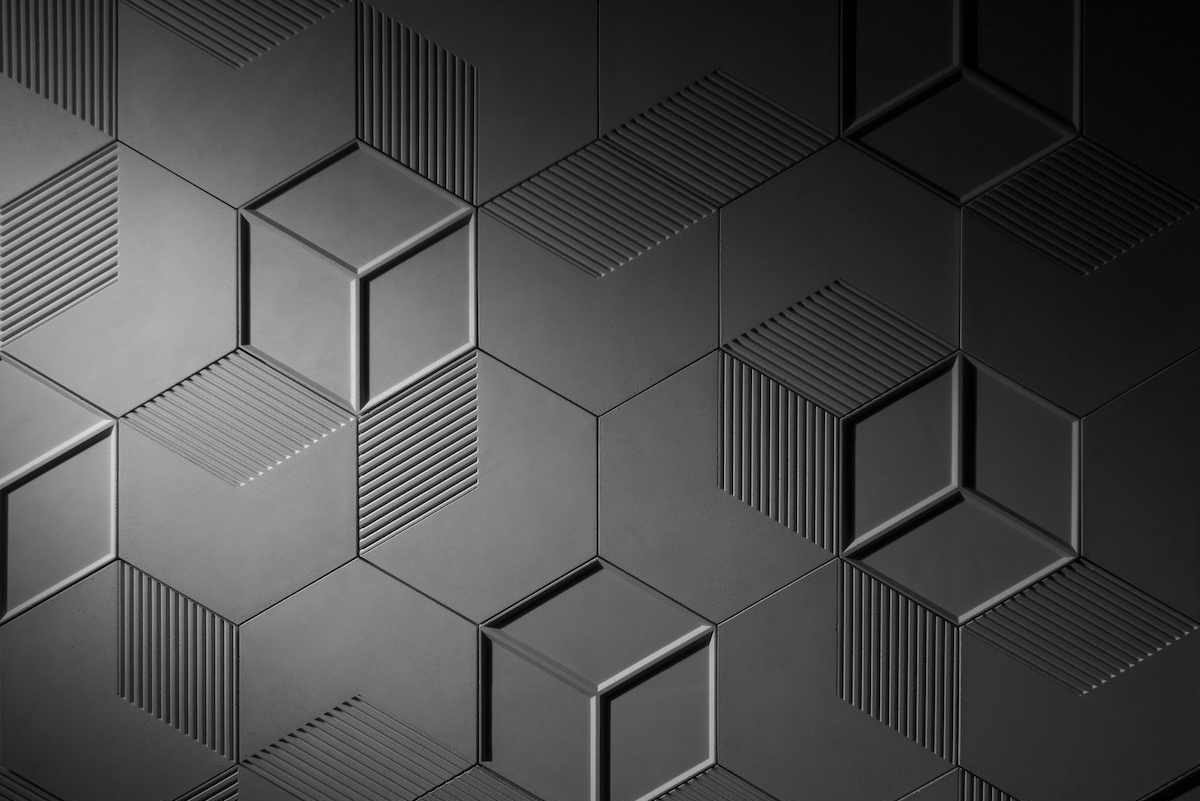

Utilization of Decorative Tiles

Decorative tiles can be applied in numerous locations throughout the house. While most people associate tiling with the floor, tiles can also be used to spruce up various other areas. They can be used in restrooms, on walls, and kitchen counters.

Tiles work well as backsplashes around bathtubs and behind sinks in the kitchen and bathroom. Using tiles as room borders is a great method to give a room a fresh look. An easy-to-maintain floor that also serves as a work of beauty can be made by replacing an old floor with new tiles.

Additionally, decorative tiles may be utilized singly. Single-scene or single-picture tiles can serve as both floor and wall art. A simple approach to making one-of-a-kind art especially suited to a certain room is to take a few plain tiles and hand-decorate them.

Benefits of Lightweight Concrete Decorative Tile

Lightweight decorative concrete tiles have various usages and benefits. A room can receive a completely new look without breaking the bank by replacing worn-out wallpaper and flooring with colorful tiles. Tiles can be used as accent pieces and borders to cover an entire floor or wall.

Durable and simple to maintain our decorative tiles. Weathering tiles, manufactured primarily for outdoor use, can be a useful source of insulation and incredibly resistant to the elements.

Obesity reduction

Wet concrete’s reduced dead load enables longer spans to be poured unsupported. This reduces labor costs and floor circle times. Reduces a structure’s dead weight from 1/3 to 1/2 the weight of regular concrete.

Thermal defense

With the rising cost and scarcity of energy sources in recent years, more focus has been placed on the need to reduce fuel consumption while maintaining and even improving comfort conditions in buildings. Lightweight concrete has a relatively low thermal conductivity, which is a property that improves with decreasing density. The fact that a solid wall of 125mm thick aerated concrete will provide thermal insulation approximately four times more than that of a 230mm clay brick wall serves as an example.

Resistance to Fire

A wall of lightweight concrete with a density of 1,100 kg/m3 and a thickness of 13 to 15 cm (5 to 6 inches) has a 5-7 hour fire resistance. With lightweight concrete with a density of 400 kg/m3 and just 0 cm thick, the same level of durability can be achieved. Lightweight concrete has a high fire rating because it is non-combustible and contains embedded air.

Noise Isolation

Lightweight concrete is ideal for impact and airborne sound absorption, making it a great material for floor screeds and partition walls.

Reduced Material Costs

A decrease in dead weight significantly lowers the amount of reinforcement steel needed for foundations. As a result, up to 10%, less steel reinforcement can be used overall in lightweight concrete.

Since no gravel is needed to create lightweight concrete, only the sand and cement mortar/paste afterward embedded in the foam, significant savings are also made in transportation, crane, and man-handling related activities (air).

The amount of concrete required can be reduced by casting very thin walls, which also requires using very little plaster.

In certain situations, gypsum putty can be placed directly before painting without plaster. Additionally, walls as thin as 50 mm can be cast. Lightweight concrete has a high flow capacity, which eliminates the need for vibration and necessitates the use of vibrating equipment/accessories.

Savings on labor and expenses

Producing lightweight concrete for casting or pouring panels, blocks, or even entire walls for houses only requires a small number of semi-skilled laborers. Steelworks, formworks, bricklaying, and cement renderings are not key site activities while creating lightweight concrete. Hence the corresponding personnel is not needed.

Workers are only required to set up the reusable, cost-effective formworks and to take them down for the subsequent casting or erection.

The less dead load, increased building rates, and cheaper hauling and handling. The eight of the building in terms of the loads transferred by the foundations is a crucial design consideration, especially in the case of tall buildings.

Sometimes it has been able to move forward with a design that would have been abandoned due to excessive weight thanks to the use of lightweight concrete.

Using lightweight concrete for the building floors, partitions, and exterior cladding of frame structures can significantly reduce costs. The haulage load for most building materials, such as clay bricks, is restricted by weight rather than volume. With the right design, containers can move far more lightweight concrete for less money. Worker productivity should increase, which should result in lower labor costs.

This may make up as much as 80% of the total price. As a result, handling expenses might also be reduced.

Lightweight concrete’s lifetime

Concrete that isn’t heavy has a shelf life (minimum 100 years). An earlier analysis revealed that just 75% of the hydrated cement was present in the sectioned blocks of cellular concrete that were cast ten years prior. With continued hydration, it is anticipated that the strength will continue to rise.

In many instances, products like clay bricks, traditional concrete blocks, and other insulation materials have been replaced by the usage of lightweight concrete.

Your comment submitted.