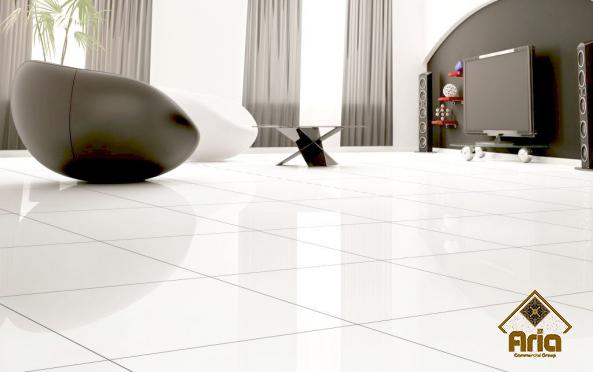

Porcelain tiles or ceramic tiles are porcelain or ceramic tiles that are commonly used to cover floors and walls and have a water absorption rate of less than 0.5%. The clay used to make porcelain tiles is generally dense. They can be glazed or unglazed. Porcelain tiles are one of the types of glass tiles and are sometimes known as porcelain glass tiles. White porcelain floor tile is one of the same types that are produced in Iran and exported to many countries. Porcelain floor tiles are very popular because of their waterproof and anti-pet capabilities. This is a very durable type of flooring. Apart from durability, porcelain floor tiles are diverse in design and help you reach the bathroom or kitchen of your dreams.

From A to Z of Producing and Distributing Porcelain Floor Tiles

Tile bodies are usually harvested from different soils in different conditions and from different mines. These ceramic tiles are made of different raw materials based on their application and role which are: plastic raw materials, fillers and melting aids or melters. The first step is to prepare the crushing of hard and coarse materials, which are turned into finer materials by a series of crushers. The next step is milling which uses ball mills. In the mill, in addition to raw materials, a little lubricant such as sodium silicate is added and this causes the final mortar to gradually turn into a lubricating slurry during damage.

Tile bodies are usually harvested from different soils in different conditions and from different mines. These ceramic tiles are made of different raw materials based on their application and role which are: plastic raw materials, fillers and melting aids or melters. The first step is to prepare the crushing of hard and coarse materials, which are turned into finer materials by a series of crushers. The next step is milling which uses ball mills. In the mill, in addition to raw materials, a little lubricant such as sodium silicate is added and this causes the final mortar to gradually turn into a lubricating slurry during damage.

To prepare the powder from the slurry, you should use a spray dryer or spray dryers. The slurry made in the mills is poured into the slurry tanks which makes it smooth, then high-pressure pumps deliver the slurry to a cylindrical chamber called a spray dryer which pours the slurry into the air. Sprayed, the slurry is exposed to hot air and cracking in this place and at the end, a soft powder is poured on the conveyor under this cylinder.

After the tile is ready. We package the bright types in such a way that they do not spoil during transportation. The tiles are then sent to dealerships and suppliers to be sold to those who need them.

Which Region Has the Most Potential for Exporting Porcelain Tiles?

In recent years, due to the imposition of severe sanctions on Iran, a fatal blow has been dealt with exports, including the export of ceramic tiles which has reduced the export of ceramic tiles to Europe by more than fifty percent. In the list of the top manufacturers in the world! With the saturation of the country’s domestic consumption of ceramic tiles, manufacturers turn to the export of ceramic tiles (or any other product), but despite the sanctions, exports also fall and as a result, production decreases. However, ceramic tiles are exported to European countries, the Middle East and neighboring countries such as Iraq and Turkey.

In recent years, due to the imposition of severe sanctions on Iran, a fatal blow has been dealt with exports, including the export of ceramic tiles which has reduced the export of ceramic tiles to Europe by more than fifty percent. In the list of the top manufacturers in the world! With the saturation of the country’s domestic consumption of ceramic tiles, manufacturers turn to the export of ceramic tiles (or any other product), but despite the sanctions, exports also fall and as a result, production decreases. However, ceramic tiles are exported to European countries, the Middle East and neighboring countries such as Iraq and Turkey.

Global Exportation of Pure Porcelain Floor Tiles from Asian Countries

However, according to the Iranian Ceramic Tile Manufacturers Association, the ceramic tile industry in Iran does not face a serious challenge in the field of raw materials. But their statistics show that there are 147 ceramic tile factories in Iran with an annual production of about 300-400. Millions of square meters of ceramic glaze are one of the main categories of products that were imported in large quantities while domestic production was lower. Ceramic glaze accounts for about 60-70% of the cost of producing ceramic tiles. Affordable energy, raw materials, resources along with local expertise helped the ceramic tile market in the country to expand at a steady pace. Iranian ceramic tiles have good markets in countries such as Iraq, Afghanistan, Pakistan, Turkmenistan, Georgia, UAE, Tajikistan, Armenia, Uzbekistan and Azerbaijan.

However, according to the Iranian Ceramic Tile Manufacturers Association, the ceramic tile industry in Iran does not face a serious challenge in the field of raw materials. But their statistics show that there are 147 ceramic tile factories in Iran with an annual production of about 300-400. Millions of square meters of ceramic glaze are one of the main categories of products that were imported in large quantities while domestic production was lower. Ceramic glaze accounts for about 60-70% of the cost of producing ceramic tiles. Affordable energy, raw materials, resources along with local expertise helped the ceramic tile market in the country to expand at a steady pace. Iranian ceramic tiles have good markets in countries such as Iraq, Afghanistan, Pakistan, Turkmenistan, Georgia, UAE, Tajikistan, Armenia, Uzbekistan and Azerbaijan.

The existence of pure minerals in Iran and the production of a good product has caused many countries to accept the product from Iran. Iranian floor tile products have become very popular in Asian countries. But there may still be challenges to exporting and selling.

Your comment submitted.