Sublimation and press the ceramic tiles are popular among some people. The best and perhaps the easiest way to do this will be explained in the present article.

On the glossy ceramic tiles, the artwork and picture reproductions appear just stunning. Through the use of sublimation printing, you can produce one-of-a-kind images that will make any home or business stand out.

Because of their susceptibility to scratching, these bespoke tiles shouldn’t be used on surfaces that need to be cleaned on a regular basis. Utilized most effectively for simply ornamental purposes, such as in tile stands or framed artwork. It is not recommended to grout.

The matte ceramic tiles have a high level of durability and are resistant to scratching, in addition to providing great photo and art reproduction. It is appropriate to use these tiles for wall murals, showers, and backsplashes in any room in homes or businesses; however, you should not use them for floors, countertops, or any applications that are exposed to the elements.

For these ceramic tiles, you can use any glue that is available for purchase in the marketplace. We recommend choosing grout that does not contain sand. These tiles are not recommended for use on any floor, countertop, or installation that is exposed to the elements. Tiles can be cleaned with any household cleanser that does not include abrasive ingredients, along with a gentle cloth or sponge.

The process of sublimating ceramic tiles is not particularly challenging; but, in order to produce the best possible results, certain procedures must be adhered to.

Because the techniques and processes involved in pressing ceramic tiles have evolved over the course of the years in response to the availability of new technologies, there is sometimes a great deal of confusion around the process. I have some ideas that I’d want to share with you so that you can produce ceramic tiles more quickly and easily, even in large quantities, and yet achieve the best potential results from your efforts.

Replace it with the new version and delete the old one.

In the “old days” of sublimation, a particular way of pressing ceramic tiles was used. After placing a piece of “blowout,” scrap paper, or Teflon below the tile, you tapped the transfer paper around the back of the tile to adhere it.

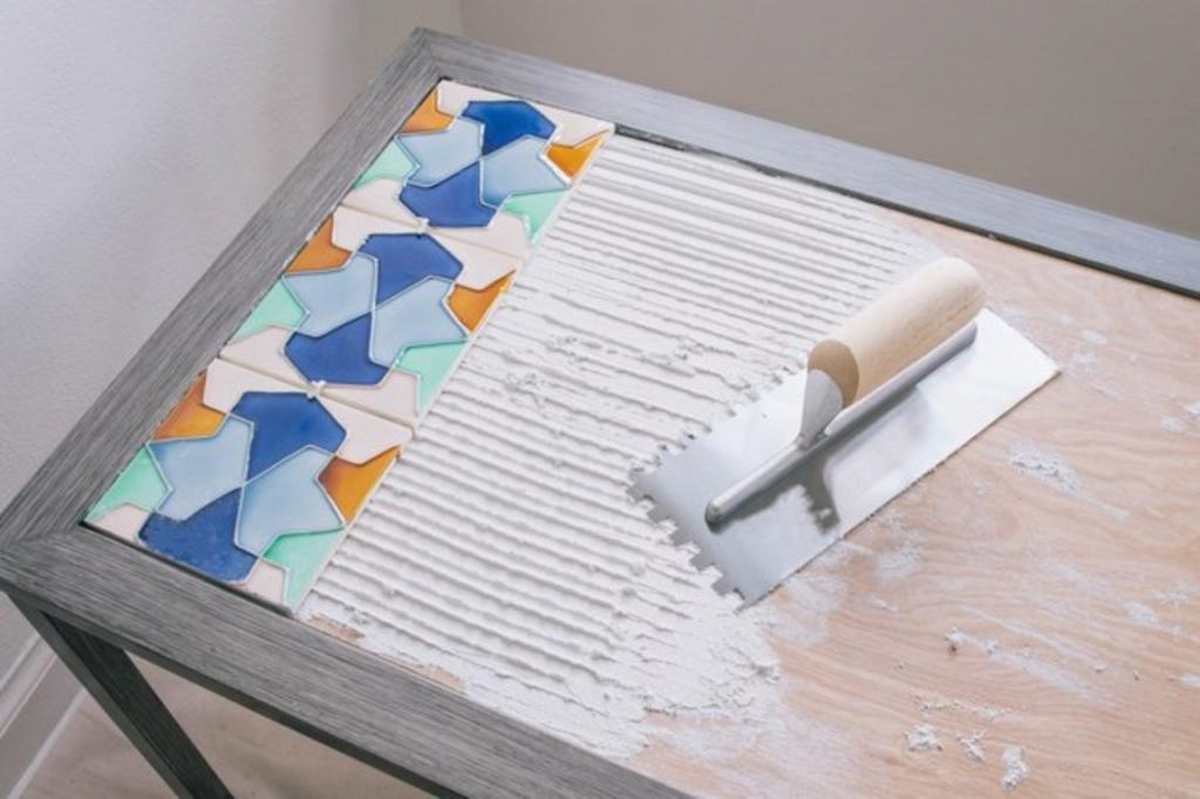

Place the tile with the glazed side down on the press and use a lot of force to press down on it. Cover the tile with another piece of “blowout” paper or Teflon. Because of the pressure, the tile was pressed down into the bottom rubber silicon pad of the heat press, which resulted in a nice wrap-around effect for the tile’s edge.

This method could be improved by placing the tile with the finished side facing up on a heat-conductive pad made of rubber and silicon and then exerting significant force. The pad was pressed up to the edge of the tile, creating an attractive wrap-around effect.

This method was successful, but it needed an exceptionally high amount of pressure. Additionally, if the tile had a soft gloss finish, the procedure would give the gloss a mottled appearance because the paper grain would be imprinted into the glossy coating.

You shattered tiles frequently because of the great pressure that you were under.

The primary drawback of utilizing this strategy is the impact that it had on your press. Because you had to press the tiles for such a long period and with such heavy pressure, the bottom rubber pad of your heat press would have a little dip because the rubber would have been squeezed as a result of the pressing process.

If you needed to press flat objects, this could be disastrous for you because you would not be able to apply consistent pressure there, which would result in a square area on your substrate that was lighter in color.

Over time, this issue would be resolved, but in the meantime, it would be resolved, it would be devastating for you. In addition to this, the rubber would keep the low point throughout time, which would need you to replace the rubber pad much sooner than would normally be required.

THEN A NEW PROCEDURE AROSE

The combination of these elements and the availability of a new product resulted in the creation of a new method for pressing ceramic tiles. In this method, the incredible Nomex Felt was utilized as the substance of choice.

Firesuits are typically made out of Nomex because it is a material that is resistant to flames. Because it is flame resistant, it performs exceptionally well when used for pressing tiles for extended periods of time.

In addition, the Nomex pads that we make use of for the sublimation process are thick and fluffy. If you push the tiles with their faces down against the Nomex pad, they will sink in and you will be able to get a wonderful wrap-around on the tile’s edge without applying an excessive amount of pressure. The Nomex pads may be used multiple times before needing to be replaced, which extends the amount of time they can be used for.

You are able to line up the tiles because they sink into the Nomex and because you push the tiles with their faces down. If you are careful, you are even able to line them up without needing tape to hold them to the paper. After you push them, they create a cute little sink hole for each tile, which will hold the tiles in place when you’re done.

After the cycle has finished, I carefully bring the press up, press down with two oven mitts on one side of the tile, and the other side of the tile lifts up. Simply turning the tile over onto the other oven mitt allows me to move it without any difficulty to the location where it will cool. If you use this strategy, you will be able to boost production pace by fast cycling tiles.

WHAT IS THE PURPOSE OF THOSE TILES HAVING A BACK SIDE?

The tile maker determines whether or not the tiles have a grid on the back of the tile. A grid is utilized while installing tiles on flat surfaces because of its installation requirements.

You need to give those a lot of careful attention, especially if the findings of your sublimation experiment are all over the place. Because ceramic is a really good heat conductor and because you are pressing the tiles face down, you want the heat to spread throughout the tile, so the back of the tile should come into contact with the heat platen portion of your heat press. This will ensure that the tile is heated evenly.

Contact is what brings about this result. While some grids include patterns that repeat themselves, others may have a large square in the middle of the grid. As a consequence of this, the completed tile could have a hazy or bright patch of color in the middle that is icy to the touch.

You can facilitate the flow of heat between these tiles by making use of the green heat conductive pad or a really mind-boggling method. You can save money and avoid having to purchase a green heat-conductive rubber pad by placing a quarter in the central square area of the pad. This will allow the heat to be transferred from the platen to the tile.

DIFFERENCES IN TILE QUALITY ARE PRESENT

There may be a significant amount of variation in both the quality of the coating and the caliber of the tiles. Tiles with a glossy finish highlight any coating variances that may exist. When too much pressure is applied to a coating that is softer than usual, the shiny surface will take on the appearance of orange peel.

It is not that the coating will become orange, but rather that it will take on the mottled appearance of an orange peel. This takes place as a result of the coating becoming excessively softer during the sublimation process.

Furthermore, if you apply an excessive amount of pressure, the grain of the paper will actually be forced into the glossy coating, resulting in the upper regions of the product taking on a matte appearance. To avoid this issue, either lessen the pressure you apply or invest in tiles with a higher quality and more durable coating.

As long as the process is carried out correctly, sublimation of ceramic tile is not difficult. If you give these methods a shot, you’ll soon be able to produce tiles with the kind of truly remarkable results for which tiles are famous.

In order to benefit from an up-to-date list of stylish tiles with diverse colors and patterns, do not hesitate to press the con box. We will be glad to work with wholesalers and importers around the world.

Your comment submitted.