it doesn’t matter what the application is, clay tiles are used for different places. They can be used as decorative tile or as coverage in exterior hot places.

The price of these tiles is based on the used raw materials. A clay tile is a ceramic product made from solid units of clay or shale or both, formed into any shape, usually, a rectangular flat shape, while malleable and fired in an oven. According to ASTM specifications, clay roof tiles are classified according to their durability and appearance.

- Level 1 – Provides resistance to the effects of severe frost.

- Level 2 – Provides moderate frost resistance.

- Level 3 – Negligible resistance to any freezing effect.

- Type I – High Profile Mosaic – Mosaic with an aspect ratio greater than 1:5.

- Type II – Low Profile Tile – Tile with an aspect ratio of 1:5 or less.

- Type III – All other tiles, including flat tiles.

Tiles must be free of defects, imperfections, or swelling that could affect tile laying/placement, roof performance, or the requirements of this code. When cracked, the tile should have black areas which give a steely appearance and contrast with the normal color around the tile.

This dark area is called the black heart or black core. The exposed surface of the tiles must be free of flaking or other appearance defects when viewed from a distance of 12 m by an observer with normal vision in the illumination of at least 50 FC (538 lm/ m).

When 50 freeze-thaw tests are performed, the tiles should show no cracking, no crack formation exceeding the minimum specimen size, and no loss of more than 0.5% dry weight. The transverse breaking strength of the slabs shall be determined in accordance with the provisions of the bending test and shall comply with the requirements.

Dimension and weight tolerances

- Dimensions

The total size variation of individual tiles must not exceed 65% of the nominal size specified by the manufacturer. The average size should not be less than the nominal size.

- Weight

The total weight variation of a single tile should not exceed 6-10% of the nominal weight specified by the supplier. The average weight should not exceed 6-10% of the nominal weight.

Advantages of clay roof tiles

- Long service life

A clay tile roof has a lifespan of about 150 years. Clay tiles are a durable material that will not be affected by the passage of time or the harshest weather conditions.

- Resistant to extreme weather conditions

Terracotta tiles are resistant to the harshest weather conditions. Clay roof tiles are resistant to extreme freezing due to the nature of their pores. However, due to rain or snow, these pores do not fill with water.

- Easy to maintain

Terracotta tile roofs are easy to maintain mainly because of the traditional shape they are available in and their very simple installation procedure.

- Suitable for sloped and curved roofs

Clay tiles are available in a variety of sizes, colors, and very simple installation techniques. Therefore, they can now be used to repair any sloping or curved roof or facade. They are even customized to match the contemporary style and aesthetics of the roof.

- Easy to handle and environmentally friendly

Another advantage of clay tiles is that they are light and easy to handle. Without a doubt, it is a valuable tool for the installation of our roofs. What’s more, it saves a lot on the shipping cost of our tiles. It is undoubtedly good for the environment as it reduces carbon monoxide emissions.

Disadvantages of clay roof tiles

- Not 100% windproof

Clay tiles are not windproof, they are more wind resistant than other roofing materials, but they can still move in strong winds or fall off the roof.

- Weight

They are much lighter than concrete tiles, but they can put a lot of load on the roof. Therefore, they are not suitable for unstable structures and may require roof reinforcement before installation.

- Brittle

Clay bricks can become brittle in cold weather. Indeed, frequent freezing and thawing weaken them. Brittle tiles are more likely to crack when subjected to pressure. Even in hot climates, clay bricks are brittle and break easily.

tiles for hot places

while you are selecting tiles for hot places and hot climates, bear in mind that these tiles must be resistant to extreme weather conditions.

As the world continues to warm, the world is experiencing an increasing number of severe weather events and prolonged periods of above average heat. In a hot climate like this, the houses bear the brunt of bad weather, and the roofs, where the sun shines all day, are the worst. But a roof isn’t just for protecting you from the sun. A poorly made roof degrades under the effect of heat, cracks, and decomposes over time. It also transfers heat from the sun directly to the house through the surface.

This process, in turn, drives up the energy cost of home cooling, making some materials much less energy efficient than others.

On the other hand, some types of roofs not only absorb heat in their stride but also provide much-needed ventilation and air circulation between the roofing material and the ground, which means the house stays cooler compared to a house with asphalt shingles.

Some materials make heat transfer more difficult or reflect sunlight from the roof, making the house as cool as a cucumber. Of course, different hot weather materials have their pros and cons. To help you weigh up the different aspects, we present a guide to the most popular thermal climate roofing materials.

There’s a reason this roofing material is so popular in the Southwest, and it has nothing to do with its appearance; however, terracotta is indeed a great option for those looking to capture a bit of Spanish colonial flair. The word terracotta literally means “soft earth” in Italian, and it’s this firing process – in a high-temperature kiln – that gives these tiles their weather resistance.

In fact, clay bricks are known to withstand high temperatures for centuries, lasting up to 50 years or more. The curved shape of the tiles also varies, allowing air to circulate beneath the surface, keeping the roof and interior cool.

The only downside to this sleek, energy-efficient option is the weight and cost of the slab materials. Terracotta tiles weigh two to four times more than traditional asphalt roofs, so many homeowners find they need to reinforce their roofs before installing terracotta in their homes.

Plus, they’re also one of the most expensive materials, costing around $700 to $1,000 per square meter (100 square feet if you’re unfamiliar with roofing terminology). However, given their long lifespan, they will likely only recoup your initial investment.

Concrete is a great option for those who like the thermal properties of terracotta but not the price. The thickness of the material means it takes longer to heat up in the sun – and therefore longer to bring the heat back into your home. For hot-weather roofs, the concrete slab is an inexpensive, albeit heavy, solution.

However, roofing suppliers also produce more aesthetically pleasing concrete tiles that are stained to give them a bit of color.

Among these options, the S tiles are one of the most energy-efficient models in their category. Like many clay bricks, they are shaped in a wavy pattern that improves air circulation between the deck and the roof surface. This has the net effect of reducing heat transfer and cooling costs.

Often referred to as rubber roofing, the EPDM membrane is not real rubber at all, but a synthetic rubber-like substance commonly referred to as ethylene propylene diene monomer. The composition of EPDM makes it exceptionally resistant in extreme conditions. In field tests, it has been shown to withstand UV rays without cracking or breaking. Its low energy cost during manufacture is often praised in life cycle analysis.

The material is particularly effective at reducing heat when coated with titanium dioxide, which gives EPDM a lighter color.

This color reflects light and heat from the roof surface into the atmosphere. However, homeowners should be careful when using these “cool roof” technologies to reduce energy consumption. The study found that this approach could have potentially dangerous side effects on the environment.

For example, Arizona State University researchers modeling the long-term effects of cool roofs showed a 4% reduction in local precipitation. This is something to consider before you go this route.

Clay tiles for exterior application

Clay tiles are available in a traditional two-piece, one-piece, and flat profiles for the exterior application. Clay tiles are designed to overlap or interlock, with protruding lips locking the tiles together and creating a seal. Many flat clay bricks fit together.

The interlocking design is recommended in areas of heavy rain or heavy snowfall. Manufacturers offer special decorative tiles to seal the voids formed in the ridges, rakes, and buttocks. This traditional two-piece style, also known as barrel or smudge clay tiles, is installed in pairs with the tile covering the pan. It offers an attractive, far-reaching look, but is laborious and expensive to install.

Variations include Roman and Greek profiles, which feature flat rather than curved tiles. Tiles are typically 8 to 12 inches wide and 16 to 19 inches long.

S-tile Spanish Terracotta Roofing Tile

The Spanish S-tiles used on the roof are one-piece tiles that have the high-end look of traditional tiles, but are easier to install. The most popular Type S tiles are approximately 13″ wide x 16 1/2″ long. Other common sizes are 8 3/4 x11 and 9 x14 inches.

Flat clay tiles

Flat terracotta tiles are laid in double thickness, like slate. These clay tiles are available in widths of 6 to 8 inches and in lengths of 12 to 18 inches. Interlocking clay roof tiles are flat or low profile, laid in a single thickness, overlapping 3 inches. They have locking channels or ribs on the sides, and the stock can also be locked to the shingles below.

Profiles and ribs add strength to the tile. Widths are usually between 9 and 13 inches and lengths between 11 and 16 inches. The two glass roof tiles are on houses in cold climates in Norway and Duluth, Minnesota.

The Guide to Best Practices for Residential Construction indicates to make tiles, wet clay is extruded through a mold or poured into a mold and fired in a kiln until the clay “vitrifies”, fusing the particles. Complete vitrification will result in a strong tile with extremely low water absorption, protecting the tile from freeze-thaw damage in cold climates or salty air in coastal areas.

Where regular freeze-thaw cycles are expected, tiles should conform to ASTM C1167 Class 1, which allows for minimal water absorption.

Class II tiles offer moderate frost resistance and Class III tiles are porous and should not be used in freeze-thaw areas. When buying clay bricks, look for a minimum 50-year warranty on durability and color fading. Costs vary greatly depending on the quality, style, and shipping distance required. In general, designs using smaller tiles will cost more material and labor.

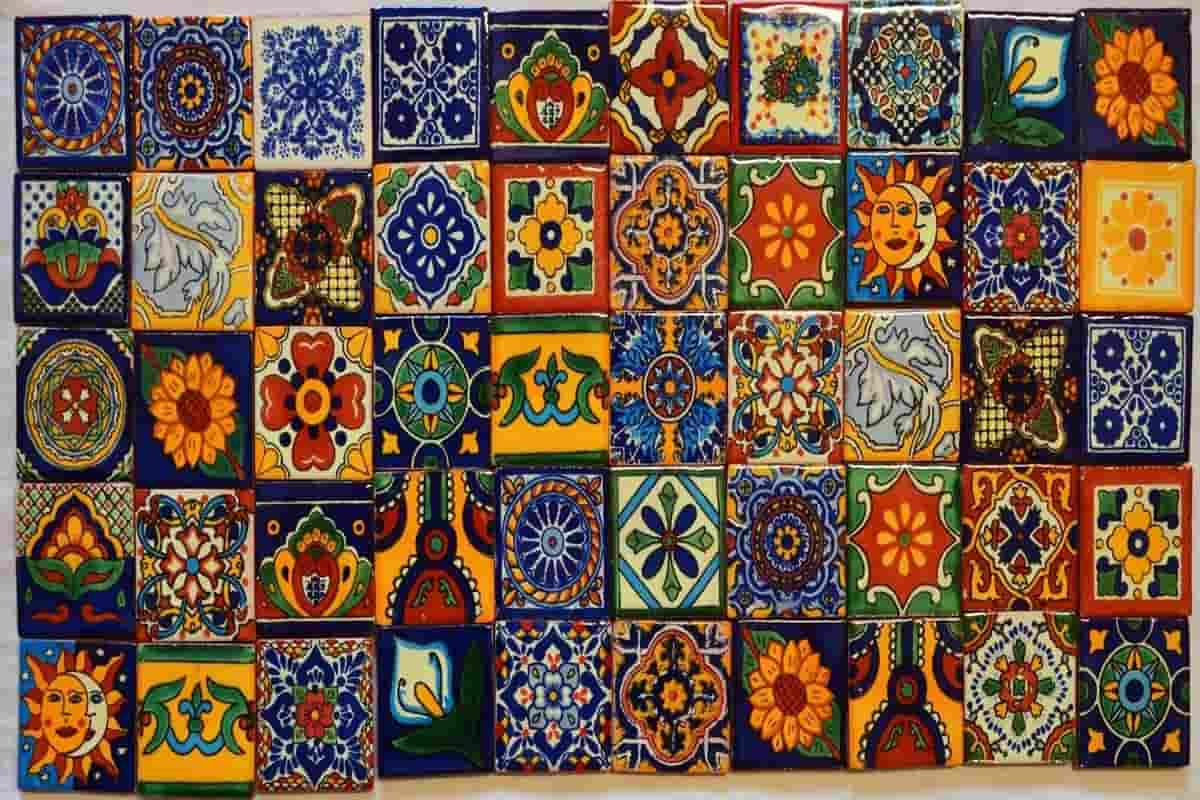

Terracotta tiles are available in a variety of colors. Transparent tiles are available in natural clay colors from light beige to pink and red.

A photo of clay roof tile shows an inserted restoration tile that does not match the original roof in color or texture. This roof apparently has other broken tiles (and leaks), apparently caused by foot traffic. Other colors can be added to the tile surface as clay grout before firing, but grout paints are only suitable for hot climates as they cannot withstand freeze-thaw cycles.

Clay tiles can also be colored with ceramic glazes to create a durable glass-like surface in almost any color. Generally speaking, clay bricks will not fade in the sun. Some jobs require installers to mix two or three different colors in random patterns. The best way to do this is to pre-mix the correct proportions of each color on the floor and send them to the roof for installation.

Your comment submitted.