The market of ceramic tile in South Africa is so vast which has a global demand and supply. In order to create a stiff end product, processed clays and other natural raw materials are often heated in the production of ceramics.

Purity, particle size, particle size distribution, and heterogeneity must all be controlled in ceramic products that start off with naturally occurring rocks and minerals. The final properties of the finished product are significantly influenced by these characteristics.

Some ceramic products start with powders that have been chemically produced. It is possible to manipulate these synthetic materials to create powders with exact chemical make-ups and particle sizes.

The ceramic particles must next be shaped into the proper shape. This is done by adding water and/or other additions, including binders, and then shaping the mixture thereafter.

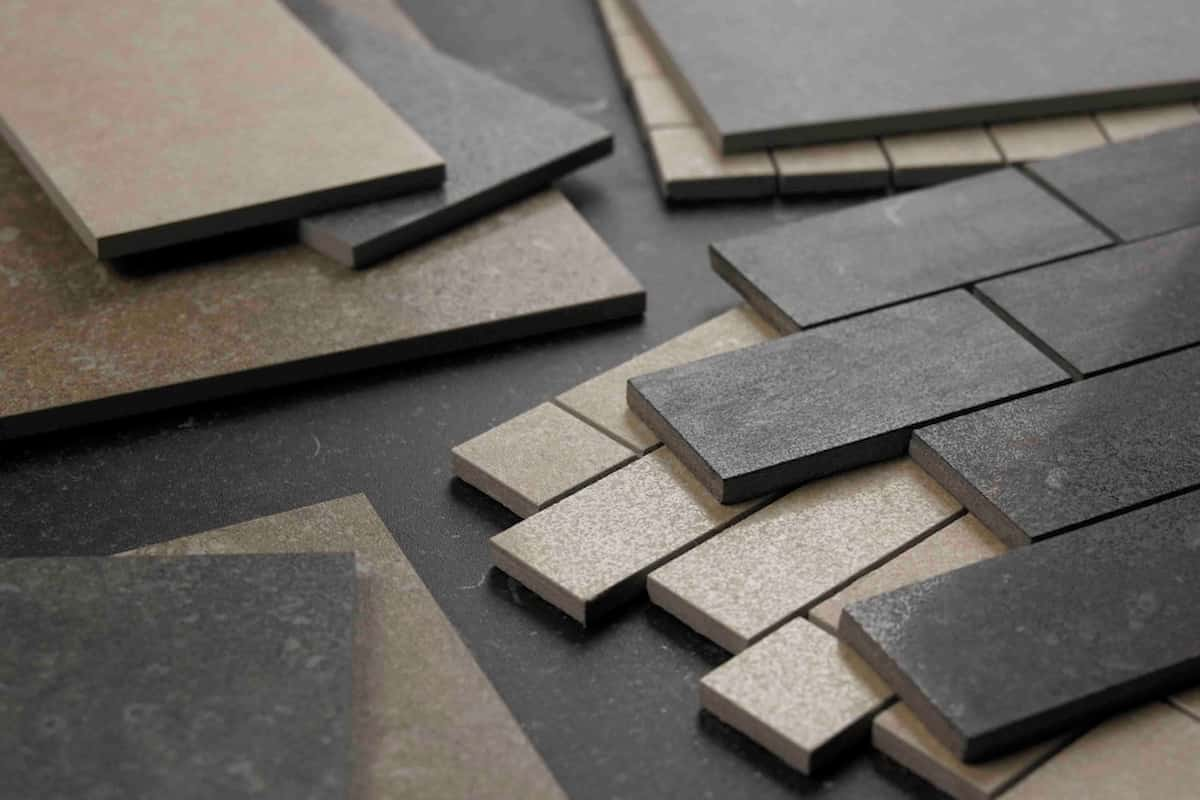

Extrusion, slip casting, pressing, tape casting, and injection moulding are a few of the most used forming processes for ceramics. These “green” ceramics go through a heat-treatment (called fire or sintering) after the particles are created to create a stiff, final product.

An further procedure known as glazing may then be applied to some ceramic items like tiles and electrical insulators. Zircon, feldspar, calcite, kaolin, and zinc oxide make up the glaze. For sophisticated applications, ceramics could go through a machining and/or polishing stage to suit particular engineering design requirements.

In 2008, the global output of tableware was 1.43 Mt, while that of sanitary and tile products was 311 million pieces and 8.495 million m2, respectively.

China was the world’s top producer of ceramic goods, accounting for 28% of the market for sanitary items, 38% of the market for all tiles, and 49% of the market for tableware. China was the top exporter of ceramic goods in 2008, accounting for 24% of all exports, followed by Italy with 14% and Germany with 11%. The top importers were the USA, which accounted for 14% of global imports, followed by Germany (8%), and France (7%).

While basic building materials are in demand in South Africa, the local production of a wide variety of consumer and business goods by the ceramics sector serves as a classic example of resource utilisation downstream.

In South Africa, Ceramic Industries Ltd. is a significant manufacturer of sanitaryware and the country’s largest producer of floor and wall tiles, accounting for 50% of local sales. In South Africa, there are 4 tile factories, 1 sanitaryware plant, and 1 acrylic bath factory.

As a result of decreasing sales volume in metropolitan regions and in the contractor markets, the tile and sanitary markets in South Africa are believed to have shrunk by 20 and 30 percent, respectively.

Four tile plants, one sanitary facility, and one acrylic bath factory make up Ceramic Industries.

Betta Sanitaryware (Krugersdorp, west of Johannesburg), which manufactures glazed porcelain sanitary ware; Vitro (west of Vereeniging, Vaal triangle), which manufactures full-bodied glazed and unglazed, extruded punched tiles for indoor and outdoor use; Pegasus (adjacent to vitro), which manufactures matt and shiny glazed, pressed floor tiles; Samca floor tiles (Hammanskraal Babelegi, T

The major seller and manufacturer of fireclay and vitreous china sanitaryware goods in South Africa is Vaal Sanitaryware, a division of Group Five Construction and Materials Manufacturing Company.

About 80% of the local sanitaryware market is supplied by Vaal Sanitaryware and Betta Sanitaryware.

- Vaal Sanitaryware (Meyerton) manufactures sanitary ceramics.

A fully owned subsidiary of Norcros UK, Johnson Tiles is a branch of Norcros SA (Pty) Ltd. One of the best ceramic tile manufacturers in the world is Johnson Tiles.

Johnson Tiles has a South African facility that produces a wide variety of floor tiles, and it is also able to import a large number of ranges from Johnson Ceramics International associate enterprises all over the world. The first company of its kind to produce glazed porcelain tiles in South Africa is Johnson Tiles.

- Johnson Tiles (Olifantsfontein) manufactures glazed porcelain and ceramic tiles.

Ceramic markets (5.1)

Ceramic clays can be divided into two primary categories: those that are fired to a dark color and are only used to make structural clay goods, and those that are typically fired to a light color and are used to make whiteware. Another differentiation is made depending on how workable or plastic the materials are, which are generally classified as plastic, semi-plastic, or low plasticity clays.

The ceramics used in this paper are divided into the following 4 groups:

FIRST WHITEWARES

Specific requirements for raw clay material must be met depending on the type of whiteware being produced. For instance, stoneware bodies must have good plasticity and firing behavior, porcelain bodies must be fired to a pure white color, and hygienic bodies must have superior casting qualities. Whitewares include ceramics for the home, floor and wall tiles, and sanitary products (decorative ceramics, dinnerware etc.).

DOMESTIC CERAMICS

The production of ceramics for the home includes dinnerware, artificial items, and decorative items manufactured of porcelain, earthenware, and fine stoneware. Plates, dishes, cups, bowls, jugs, and vases are examples of typical goods.

PRODUCTS MADE OF STRUCTUAL CLAY

The most popular structural clay items include clay floor and wall tiles, clay pipes, roofing tiles, and bricks.

TECHNICAL CERAMICS,

Technical ceramics producers provide a wide range of goods that are partially based on synthetic raw materials and partly on clays. The raw ingredients are burnt in kilns, just like they are in the other ceramic industries.

Modern ceramics include:

Bioceramics, cutting edges, and engine parts are structural.

electrical components such as magnets, superconductors, insulators, integrated circuit packages, and capacitors

Engine parts, cutting tools, and industrial wear parts coated

Environmental and chemical – catalyst support, membranes, filters, and catalysts

Imports, particularly from China and Italy, dominate the South African ceramics market. Over the past five years, imports of ceramic products have increased at an average pace of 22.5 percent. Due to the worldwide economic crisis, purchasing started to decline in 2008.

In 2009, South Africa brought in R2 615 million worth of ceramic items, or around 183 Mt. More over half of the imported ceramic products were laboratory equipment.

15.2 Mt of ceramic items were exported from South Africa, totaling R408 million. 30 and 25 percent of the exported ceramic material were made up of glazed ceramics and ceramic construction blocks, respectively.

Our professional negotiators are eager to receive your message in order to begin a prosperous relationship for both sides.

Your comment submitted.