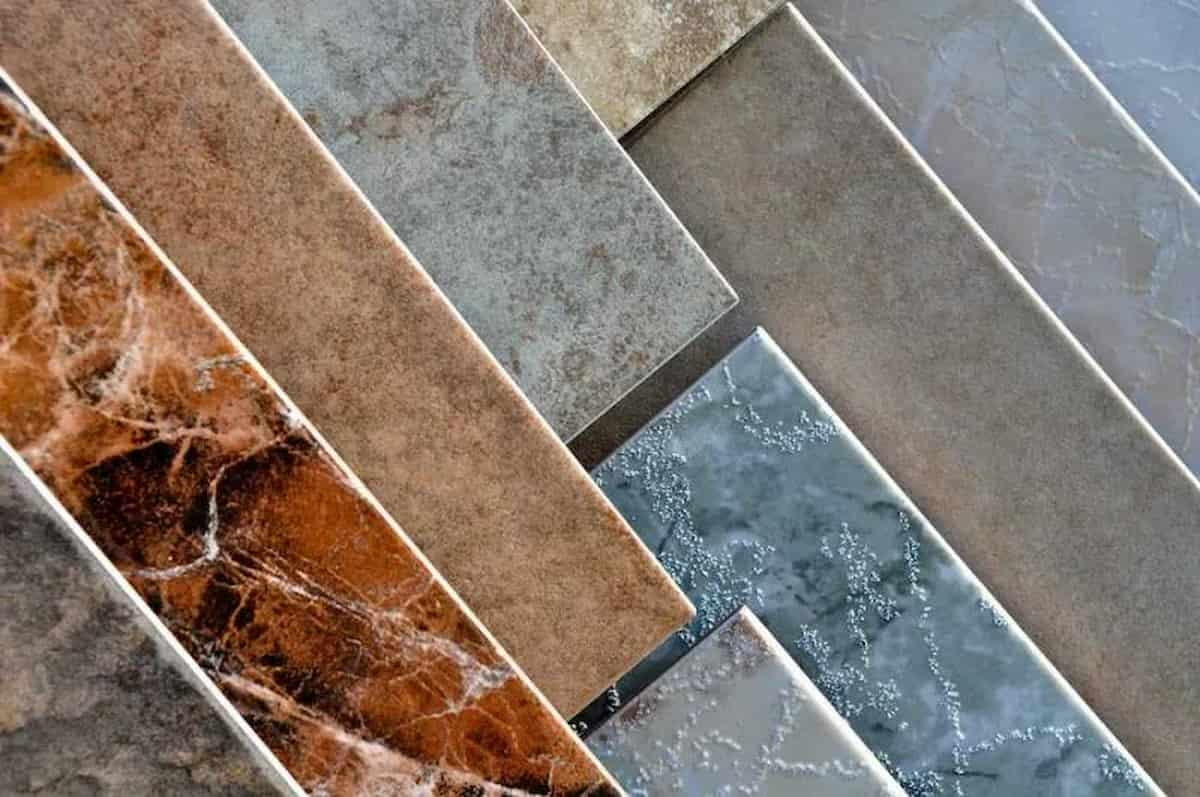

South Africa, as one of the greatest manufacturers of tile uses different raw materials to produce tiles. Some examples are feldspar, silica, kaolin, clay and talc to new a few.

To match the diversity of its product line, the ceramic sector uses a vast variety of materials, both natural and manmade.

The majority of the materials thought to be in abundant availability are utilized in the production of traditional ceramics, with a fair amount also being employed in minor quantities in more sophisticated applications.

Feldspar Raw Material

As the first raw material, the term “feldspar” refers to a class of minerals defined by the presence of silica and aluminum (Al) (SiO4). These silicates of aluminum with sodium oxide, potassium oxide, or calcium oxide are included in this category. The most prevalent mineral family on earth is feldspar.

This group of minerals consists of orthoclase, microcline, and plagioclase feldspar.

They can arise in a number of temperature settings, such as when magma crystallizes, when rocks undergo metamorphism, and during sedimentary processes. Large granite masses, pegmatites, and feldspar-rich sands are all sources of feldspar for mining.

In 2009, 18.9 Mt of feldspar were produced globally. Turkey had the highest production rate at 26%, followed by Italy in second place with 25% and China in third place with 11%. With 0.5 percent of global output, South Africa has a negligible impact.

Feldspar can be found in granite and pegmatite bodies in South Africa. In the Northern Cape and Limpopo provinces, feldspar-bearing pegmatites can be found in the Mica and Gravelotte regions. Pegmatites are typically connected to the Swazian-aged Goudplaats Gneiss in the province of Limpopo.

The Northern Cape’s pegmatites are restricted to a belt that is roughly 550 km long and between 15 and 30 km wide.

The Vioolsdrif, Hoogoor, and Keimoes Suites, as well as metamorphic rocks nearby, are connected with them. These tectonic intrusive rock units are all of Mokolian age.

The majority of pegmatites exhibit some degree of zoning, and because their cores typically include quartz and microcline-perthite, many of the larger zoned bodies are ideal for the production of potassium feldspar.

Despite having a usually dyke-like appearance at the surface, the pegmatite bodies in South Africa are known for having surprising vertical morphologies.

As a result, it is typically quite challenging to assess pegmatite mineral reserves with accuracy. However, regional feldspar reserves are sufficient to supply the nation’s medium- to long-term needs, according to surveys conducted on the major pegmatite fields since 1960.

For high grade ceramics, the allowed impurities in ceramic feldspar (both K-feldspar and Na Feldspar) should not exceed 0.1% Fe2O3, while for standard grade, they shouldn’t exceed 0.3% Fe2O3.

The production of ceramics and glass are the two primary industries that employ feldspar as a viable source of alumina and alkali.

It is used in dinnerware, ceramic glazes, and white ceramic pottery. Other minerals with comparable qualities to feldspar include pyrophyllite, clays, talc, and quartz. However, for the foreseeable future, its availability renders these alternatives obsolete.

Due to the high demand from the ceramic and glass industries, feldspar production in South Africa has been growing at an average annual rate of 5.7 percent for the past 10 years. Approximately 85 to 90 percent of feldspar is consumed by these sectors.

Silica Raw Material

Silicon dioxide, usually referred to as silica, is an oxide of silicon with the chemical formula SiO2 which is a very appropriate raw material. In nature, silica is most frequently found as quartz, which can be found in five different forms: sand, quartzite, large quartz, quartz crystals, and silcrete.

After feldspar, silica is the mineral that is most prevalent in the Earth’s crust. It serves as the raw material for the manufacture of ceramics and silicate glasses.

Due to a lack of demand from significant consumer markets, silica production fell by 7.4% in 2009 to 112 Mt from 121 Mt in 2008. With 24.5 percent of the world’s total production, the United States continues to be the largest producer and user of silica.

Italy and Germany are next with 12.5 and 5.8 percent, respectively. 2.6% of the world’s production came from South Africa.

In South Africa, the provinces of Gauteng, Limpopo, Mpumalanga, and Eastern Cape contain significant silica deposits. A high grade quartzite may be found in the Belfast and Moabsvelden areas of the Mpumalanga Province, both of which are about 10 kilometers east of Delmas.

These deposits are made up of incredibly pure quartz (arenites), and they have the potential to produce high grade SiO2.

The ore body at the Witkop Silica Mine in the Limpopo Province contains roughly four quartz pods that are separated from one another by zones of granite gneiss (Turfloop Granite) that have a quartz grade of 55%. This mine is located 4 km to the southeast of Polokwane.

The ore deposit, which is found in massive form in the Phalaborwa region, is exploited for its mica, vermiculite, feldspar, and silica content.

Glass, ceramics, and chemicals are made mostly with silica. With applications in the chemical, metallurgical, and electronic industries, lump silica is primarily utilized as a flux in the production of silicon and ferrosilicon.

Due to the significant demand from the construction sector in the run-up to the 2010 FIFA World Cup, South Africa’s silica production increased at an average annual rate of 4.2 percent between 2000 and 2009 (Fig. 4). The fall in 2009, however, was brought primarily by a decline in demand from other significant consumer markets.

Kaolin Raw Material

Another raw material is Kaolin whose term refers to a naturally occurring, white, fine-grained, non-plastic, earthy substance that is mostly made of the mineral kaolinite, a hydrated oxide of silica and alumina. There are two types of kaolin deposits: primary and secondary.

While secondary kaolins are sedimentary in origin, primary kaolins are produced by residual weathering or hydrothermal alteration of alkali feldspar-rich rocks like granite or gneiss. Both main and secondary deposits can be found in South Africa.

Compared to 2008, when it was 35.9 Mt, global kaolin production fell by 14.8% to 30.6 Mt in 2009. The world paper markets’ decreased demand was the cause of this.

United States is the world’s top producer, accounting for 17% of global production, followed by Uzbekistan at 15%, the Czech Republic, and Germany at 11% and 10.6%, respectively.

The estimated 110 Mt of kaolin reserves in South Africa contain 46 to 73 percent silica (SiO2) and 19 to 38 percent alumina (Al2O3 ). Economic deposits can be found in the Grahamstown region of the Eastern Cape, the Cape Peninsula, and the Pretoria/Bronkhorstspruit region (Gauteng).

Kaolin was produced in South Africa in 2009 in an amount of 30.1 kt (Fig. 6). Due to dwindling paper industry demand and low-cost ceramic imports from China, Korea, and Vietnam during the past 10 years, South Africa’s kaolin production has been declining at an annual rate of 11%.

The paper and ceramics sectors, which together account for more than 60% of kaolin consumption, are its biggest consumers.

Quality white ceramics like porcelain and earthenware dishes are the major uses for kaolin. Although other characteristics like particle size and dry strength are typically specified, color is a crucial criterion.

Although there is a considerable variety of ceramic kaolin, many of the grades are only made for conventional uses.

Clay Raw Material

Ball clay is mostly made of kaolinite and have fine-grained organic content, which gives them good plastic characteristics as a popular raw material.

Ball clays are a common element in clay bodies made primarily of non-plastic minerals including kaolin, feldspar, and silica in the whiteware ceramic industry.

Four areas in the world produce the best ball clays for the ceramics industry: Devon and Dorset in the UK, Kentucky, Tennessee, and Texas in the USA, northern Thailand, and central Europe.

Illite is the main mineral in several clays. The phrase “plastic clays” is used in these circumstances.

However, ball clays and plastic clays are the same thing in the industrial context. High quality ball clay is mostly produced and exported by the UK.

Ball clays can be found in South Africa’s Western Cape (Stellenbosch region) and Mpumalanga Province (Carolina District). In the Western Cape, plastic clay has been utilized for many years, primarily for the whiteware ceramics industry.

Ball clays are employed in a variety of sectors, but they are especially important in the production of ceramics.

When used alone, kaolin is brittle and weak and must be combined with ball clay to create a workable, pliable raw material. When burnt, kaolin produces a very white color.

The ceramics industry values these clays for their white-firing qualities, which are influenced by the concentrations of iron and other coloring/fluxing oxides in the clay. Ball clays are most commonly used in the ceramics sector, which is controlled by the tile and sanitaryware markets.

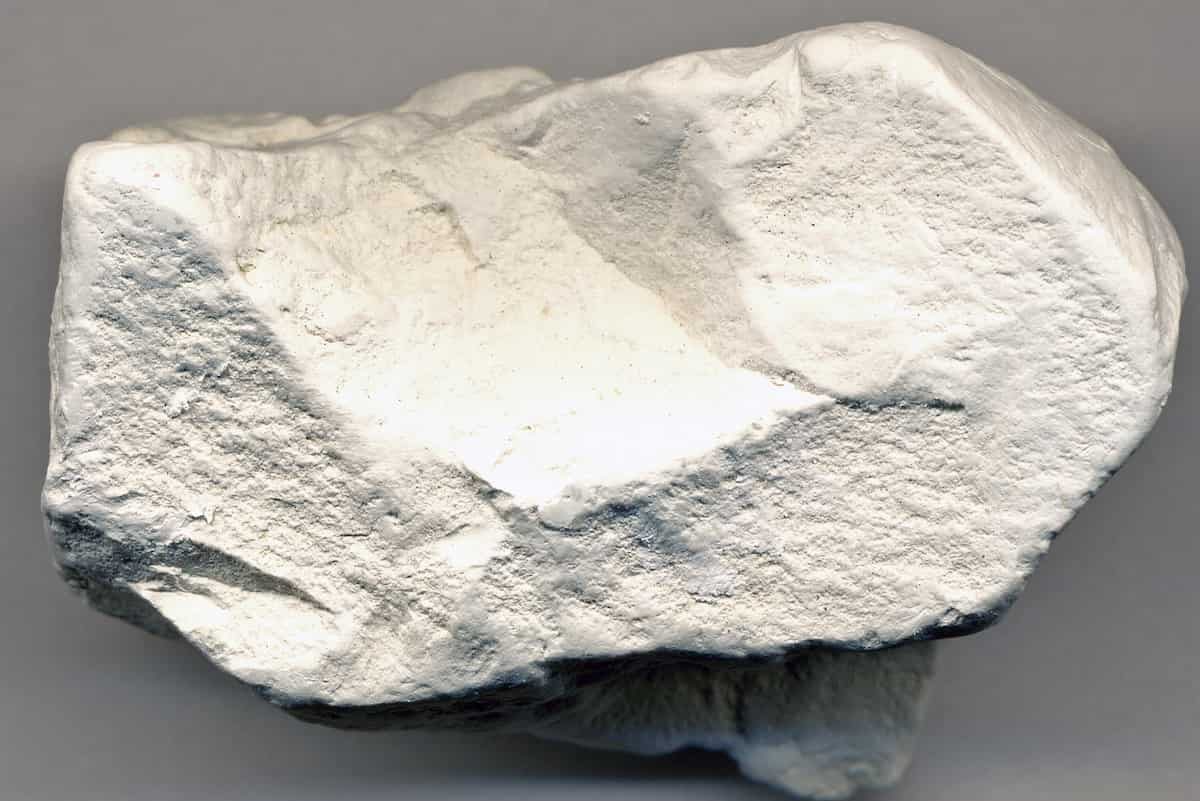

Talc Raw Material

The last raw material in the present paper, from the Arabic word “talq,” which means mica, talc is a hydrated magnesium silicate.

Talc has excellent basal cleavage, which enables it to separate into wavy, flexible, nonelastic flakes, and is similar to mica in that it can be found in sheet-like bulk, be foliated or seem scaly.

Steatite is a common name for pure, enormous talc orebodies. Talc’s intrinsic softness, smoothness, lubricative properties, chemical inertness, high oil absorption, low thermal and electrical conductivity, high melting point, low thermal expansion, and most notably, its whiteness, all contribute to its industrial value.

Pyrophyllite and talc have similar crystal structures, bonds, cleavages, hardness, densities, and optical characteristics.

Although talc is hydrophobic (does not attract water), it is a good organic adsorbent and is frequently found in talcum powders.

The majority of economically significant talc deposits are created either by the metamorphism (contact or regional) of dolomitic sediments or by the alteration of mafic and ultramafic rocks.

Commercial-grade pyrophyllite is frequently found in vast quantities in South Africa, especially in the Ottosdal region (North West Province).

Due to a lack of demand from significant markets, global talc production fell by 4% in 2009 to 7 212 kt from 7 510 kt.

With 31% of global production, China is the world’s top talc producer. India and Korea follow, contributing 11 and 9 percent respectively.

Talc deposits that are commercially viable can be found in the Barberton and Nelspruit regions of the province of Mpumalanga.

Numerous talc deposits are found in the Barberton Greenstone Belt rocks, some of which have been used for mining.

Even while there are occasionally isolated pods of high-quality talc, the talc is typically very impure and of an industrial grade.

Other deposits can be found in the Northern Cape Province, the Chuniespoort Group of the Transvaal Supergroup in Gauteng, the Messina District of the Limpopo Province, the Nqutu District, and the Tugela Valley between Kranskop and Eshowe in Kwazulu-Natal Province ( Gordonia, Prieska, Kuruman, Barkly West and Kimberly Districts).

Around 80% of the world’s talc demand is made up of paints (21%), paper (20%), ceramics (28%), and plastics (10%)

. The building (paint, ceramics, and plastics) and paper sectors both rely on the talc market. However, talc’s main market drivers at the moment are the housing sector (for talc usage in ceramics/roofing/paint), the automobile industry (for talc use in autoplastics), and the advertising industry (for talc consumption in the paper market).

Industrial talc, often known as talc, is a key ingredient used in the production of ceramics, different types of porcelain, floor and wall tiles, electrical insulators, and refractories.

More than 30% of the talc produced is used in ceramics. A sizable building sector, where ceramics are common, is necessary for the markets for different types of ceramics.

Since 2000, talc output has been growing at an average yearly rate of 7.4%. However, as a result of the drop in demand from the residential building industry, production fell by 64% to 5.1 kt in 2008 and further to 4.7 kt in 2009.

due to a decline in demand for products used in the construction industry, including adhesives, ceramic tiles, joint compounds, paint, roofing, rubber, and sealants.

Our professional negotiators are eager to receive your message in order to begin a prosperous relationship for both sides.

Your comment submitted.